UKL Kammprofile Gasket-The future Heat Exchanger Gasket

Uni Klinger Kammprofile gasket is comprised of concentrically serrated solid metal core with soft, confirmable sealing material bonded to each face.

The soft facing material protect the flange surface from damage in addition to providing an excellent seal at low bolt stress while the serrated geometry of the metal core enhances sealing performance by inducing stress concentration on the sealing surface. The serration minimizes lateral movement of the facing material, while the metal core provides rigidity and blowout resistance. Kammprofile is an ideal replacement for problem applications associated with metal jacketed gaskets especially in heat exchangers.

Design features.

- Suitable for low seating stress.

- Optimum combination of solid core with soft sealing face.

- Configured in standard shapes for heat exchanger application.

- Standard sealing materials of flexible graphite, PTFE etc.

- Metal cores available in soft iron, stainless steel and exotic materials.

Superior performance.

- Maintains a tight seal over variable range of bolt stresses.

- Permits a tighter joint under elevated operating conditions.

- Results in reduced emissions.

- Improves efficiency of plant and machinery.

- Easy to install and remove.

Advantages of Kammprofile Gaskets

- Seals pressure up to 250 bar

- Easy to remove without damage to flange surface.

- Adaptable to suit existing arrangements without modification.

- Less sensitive to assembly faults.(inaccurate bolt tensioning)

- Reduces maintenance cost.

- The serrated metal core can be reused, subject to inspection after cleaning & re-layering.

Application areas.

- Suitable for standard ASME flanges as well as weaker and non circular flanges.

- Handles pressure from vacuum to Class 2500.

- Withstands temperature from cryogenics to 1090 deg.C depending on sealing material and metal.

- Economical replacement for jacketed heat exchanger gasket.

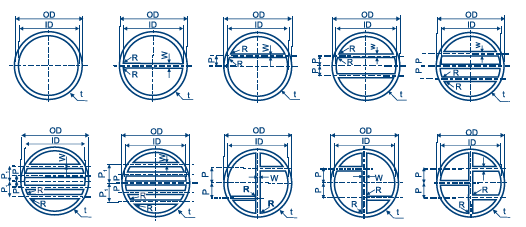

Standard Types available.

Type A: Normally used in male/female, tongue groove, and other flange configurations.

Type B: Provided with an integral outer locating ring for proper gasket positioning within the flange bolt circle suitable for raised face flat face flanges.

Type C: Similar to type B except with a loose fitting independent centering ring. The loose fitting ring allows for expansion and contraction due to mechanical and thermal shock without excessive stress being induced in the solid metal core thus reduces the possibility of damage to the core.

Ideal for Heat Exchanger flanges.

The UKL Kammprofile gasket is proving to be especially suitable as a reliable, cost effective alternative to jacketed gaskets that are commonly used in heat exchanger applications. UKL Kammprofile gaskets are suitable for use on TEMA flanges, and when required, pass partition ribs can be supplied in any configuration as in jacketed gaskets. These gaskets provides a high integrity, low seating stress seal thus ideal for heat exchanger applications with limited bolt load or lighter weight flanges.

Schematic showing typical heat exchanger gasket having pass partition plate.

Dimension:

The UKL Kammprofile gaskets can be manufactured in various shapes and sizes upon request.

Thickness of metallic core material: Generally in 3mm but for gaskets with diameter above 1.5m it is suggested in 4mm thickness.

Thickness of sealing layer: Generally in 0.5mm on each side.

Normal cam pitch: 1mm, groove depth: 0.4mm. Alternative profiles are available on request.

The ideal flange surface finish for the UKL Kammprofile gasket is 125-250 RMS.

Click here to Read More

Aerated Concrete Block Industry

Aerated Concrete Block Industry  Brewery Industry

Brewery Industry  Captive Cogen Industry

Captive Cogen Industry  Chemical Industry

Chemical Industry  Dairy Industry

Dairy Industry  Edible Oil Industry

Edible Oil Industry  Fertilizer Industry

Fertilizer Industry  Hotel Industry

Hotel Industry  Pharma Industry

Pharma Industry  Rice Industry

Rice Industry  Rubber Industry

Rubber Industry  Soap Industry

Soap Industry  Sugar Industry

Sugar Industry  Textile Industry

Textile Industry  Tyre Industry

Tyre Industry