Types of Safety Valve

The following types of Safety Valves:

- Conventional Spring-Loaded Safety Valves

- Balance Pressure Safety Valves

|

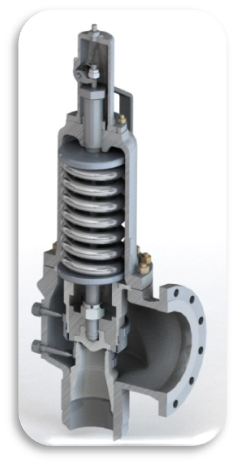

Conventional Safety Valve is designed to open at predetermined pressure and protect a vessel or system excess pressure by removing or relieving fluid from the vessel or system. The basic elements of a spring-loaded PRV include an inlet nozzle connected to the vessel or system to be protected, a movable disc that controls the flow through the nozzle, a spring the controls the position of the disc. Under the normal system operating conditions, the pressure at the inlet is below the set pressure & the disc is seated on the nozzle preventing flow through the nozzle |

|

|

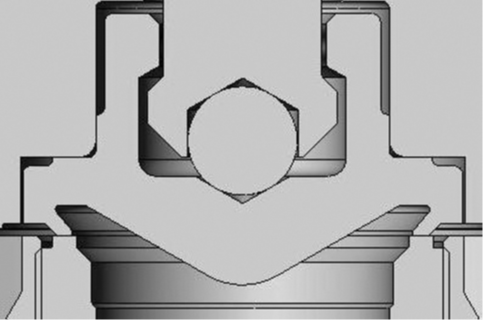

Balanced Safety Valve incorporates a bellow which balances the Valve disc to minimize the effects of back pressure on the performance characteristics of the valve. Bellow is used in Safety valve when there is variable superimposed back pressure, the built-up back pressure during discharge is greater than 10% of the set pressure. Also it is used to separate the disc-guide, the spring and all the parts inside the bonnet from the process fluid when the latter is corrosive, viscous, could crystallize or leave deposits and incrustations.

|

Safety Valves are consisting of spring loaded, full nozzle, full lift type and is approved by Indian Boiler Regulation 1950. Safety Valve can be supplied with IBR Form IIIc.

Safety Valves Sizing and calculations are in accordance with API 520 PART-I & EN ISO 4126-7. Body thickness complies to ASME B 16.34 standard. Safety valves satisfy the requirements of the standard API 526 Flanges comply to ASME B 16.5

All pressurized components are hydraulically tested. Seat tightness test us performed at 95% of the set pressure allowing operating pressure very close to the set pressure of safety valves. Seat Tightness is performed as per API 527 to maintain allowable bubbles per minutes (at 90% of set pressure). Our valves tested at 95% of the set pressure to ensure minimum or even no LEAK. Standardization of the components of the valve reduces the spare parts number. The high flow coefficient allows the most economical sizing of the valve. The blow down value of safety valve 5% to 7% of the set pressure. The value shall not be lower than 0.25 Bar and depends on the operating conditions, the type of fluid & position of the blowdown ring which is positioned in valve with external adjustment. External Blowdown Adjustment permits Blowdown to be adjusted from 5 to 7% High Discharge coefficient of safety valve permits economical sizing. Safety Valve can be offered Accessories with Lifting Lever, Test gag & Bellow on request.

This range of spring loaded conventional and balanced safety relief valves is specifically designed for overpressure protection of unfired pressure vessel (ASME Section VIII application).

- Sizes and orifices are from 1” D 2” to 8” T 10”, face to face dimensions are in accordance to API526.

- Available set pressure range is from 0.4 Bar to 414 Bar and for pressure ratings up to 2500#.

- Different material of construction can be selected, depending on the application.

- Media: Gas, Steam and Liquid.

- Orifices: from “D” to “T” in accordance to API 526; intermediate orifices (K2, P2, Q2, R2) and orifices up to 1520.5 cm2 available

- Set pressure range: From 0.4 bar to 414 Bar.

- Temperature range: From -267 Deg C to 715 Deg C.

- Over pressure: Gas 10%, Steam 5% & 10%, Liquid 10% & 21%.

- Blow down : Gas and Steam 5% to 7%

- Materials: Carbon Steel, Alloy Steel, Hastelloy, Monel and other material upon request.

|

|

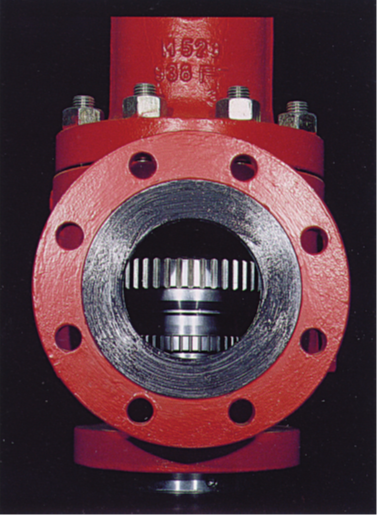

Direct spring-operated pressure relief valves has been designed to protect against excess pressure steam boilers and to provide superior performance.

These valves are designed and manufactured according to ASME Sect. I and are approved according to IBR 1950 regulation.

Double blow-down ring guarantees the over-pressure and the reseating-pressure required on section I of the ASME code. Special design of the disc eliminates the distortion due to thermal stress for maximum seat tightness. Available with open or closed bonnet.

- Flanged, Butt weld spring loaded, direct acting, full nozzle safety relief valves for steam service (ASME Sect.I).

- Media: steam (suitable also for gas).

- Orifice Sizes: From “D” to “T “

- Set pressure range: up to 153 bar.

- Temperature range: up to 566 °C.

- Overpressure: 3% or 0.14 bar.

- Blowdown: 4% or 0.28 bar.

- Size inlet & outlet: from NPS 1 to NPS 8 & from NPS 2

Feature 1: ADJUSTEMENT RING

|

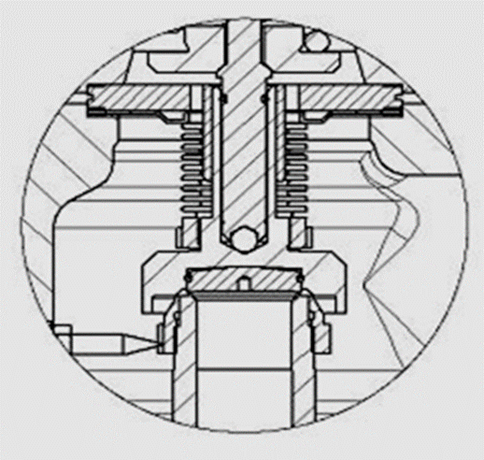

Safety valves series SMS-7100 have two adjustment rings, the lower one mounted on the nozzle and the upper one mounted on the guide. The position of the two adjustment rings modifies the performances of the valve as far as overpressure and blowdown are concerned; their position is settled and sealed at the our factory in such a way to satisfy a variety of applications. lf operation on site were not satisfactory (simmer or high blowdown), it is possible to modify the position of the adjustment rings. Lifting the lower ring will improve the pop-action effect, i.e.. overpressure decreases; by lowering it the opposite effect will be obtained. |

- Valve bodies are heavy duty design

- Full nozzle design

- Flanges can be manufactured according to a wide range of standards

- Dual blow-down ring for more precise performance: 3% over pressure and 4% blow-down

- All pressurized parts are hydraulically tested

- Seats lapped to optical flatness for tight shut-off

- The high flow coefficients allow the most economical sizing of the valve

- Among foreign certifications

- Ease maintenance

- Proven reliability

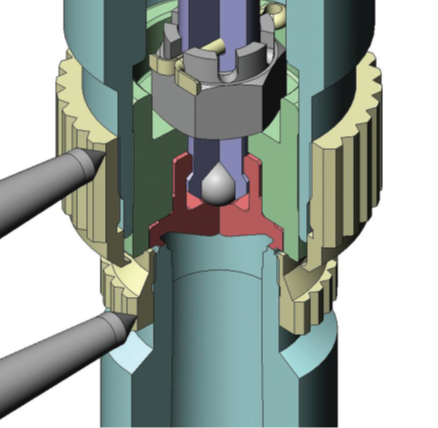

Feature 2 : DISC DESIGN

|

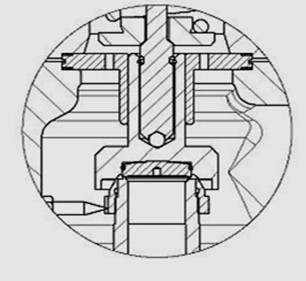

The special geometry of the disc’s seal lip allows to minimize the thermal stresses, avoiding the distortions that cause leaks through the seats. The load is transferred from the stem to the disc through a ball; this feature, together with the low positioning of the centre of thrust, helps the homogeneous distribution of the forces on the sealing surface and minimizes the side shifting of the disc from the nozzle while opening and closing the valve. These structural features, together with a scrupulous lapping of the seats, contribute to obtain high tightness of these seats and set pressure reproducibility. |

|

Feature 3: OTHER TECHNICAL FEATURES

|

Body: always from casting Body thickness: according to ASME B16.34 Flanges: according to ASME B16.5 (DIN, EN and other constructions upon request). Bonnet: may be closed (always kept at atmospheric pressure) or open Lifting lever: always supplied Tightness test: done with more severe limits than API 527 Minimum set pressure: 1 bar Max service temperature: 540 °C Set pressure adjusting range without changing the spring: ±5% of factory setting. |

Aerated Concrete Block Industry

Aerated Concrete Block Industry  Brewery Industry

Brewery Industry  Captive Cogen Industry

Captive Cogen Industry  Chemical Industry

Chemical Industry  Dairy Industry

Dairy Industry  Edible Oil Industry

Edible Oil Industry  Fertilizer Industry

Fertilizer Industry  Hotel Industry

Hotel Industry  Pharma Industry

Pharma Industry  Rice Industry

Rice Industry  Rubber Industry

Rubber Industry  Soap Industry

Soap Industry  Sugar Industry

Sugar Industry  Textile Industry

Textile Industry  Tyre Industry

Tyre Industry