Steam Trap Selection by Understanding Specifications

UNI KLINGER having various type of steam traps design irrespective to service & criticality

As like,

- Thermodynamic steam trap (UTD)

- Thermostatic steam trap (UTST)

- Bi-metallic steam traps

- Inverted bucket steam trap (UIBT)

- Ball Float steam trap (UFT)

How to select Traps & which parameters can be affect on steam trap performance &it’s efficiency:

Selection on Steam trap:

- Know your service/ application

- Location of trap i.e. reactor/ direct heating/ Indirect heating/ type of equipment coil (Jacketed/ Limpet coil)

- Total Qty of steam/ Condensate (Kg/hr)

- Operating pressure (Kg/cm2 g/ Bar g)

- Steam Inlet line size (NB/mm/ DN)

- Design Pressure drop of equipment (Reactor/ heat exchanger)

- Back pressure (Kg/cm2 g/ Bar g)

- Differential Pressure (Kg/cm2 g/ Bar g) which Inlet of traps & back pressure of downstream of trap (i.e. Delta P)

- Moreover, area where trap to be installed like atmospheric condition so that material of trap can be selected

- Sight Glass require wherever trap is in close system

Parameters which can affect on steam trap performance:

- Back pressure

- Under sizing of steam trap against high load

- Material of selection

- Customer don’t have exact detail of plant

- Wrong selection

- Wrong installation (Vertical/ Horizontal)

- Wrong differential selection of trap/ model

- End connection of trap against MOC of trap

For e.g.:

Service- Indirect steam heating limpet coil reactor

Steam Inlet Pressure- 3 bar g

Inlet size- 50 NB

Steam/ Condensate Flow- 380 Kg/hr

Pressure Drop of equipment- 0.5 bar g

Back pressure- 0.2 bar g

Selected Trap:

UKL Ball Float trap, Model- UFT 14 CI, DP- 4.5 Bar, Non IBR

End connection- SCR to BSP/ BSPT/ NPT

OrUFT 20 CS, DP-4.5 Bar, Non IBR End connection- F/E 150#

Size- 25 NB, 1 no. Qty

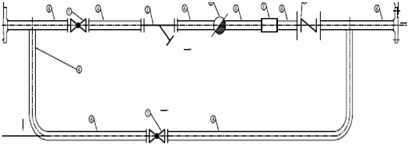

How Trap assembly looks:

CLOSED LOOP

OPEN LOOP

Selection on Trap selection:

Wherever for ease of maintenance, cleaning of trap always do prefer Flanged end connection trap so that trap can be remove within time & maintenance can be done immediately,

Now if in case very LP steam pressure application & prefers to install cast Iron then in such case choose screwed ends to BSP/ BSPT/ NPT,

In high pressure application above 10 Bar g & max do prefer Socket weld end so that chances of leakage will be very less because in sometime it may happens due to gasket wrong selection & gasket self life frequently leakage is occurs and then removal of trap time continues.

However in such case during welding procedure will require qualified IBR welders & whenever removal/ replacement of trap that time removal of cost & re-fitment cost is very high compare to screwed ends and Flanged end connections.

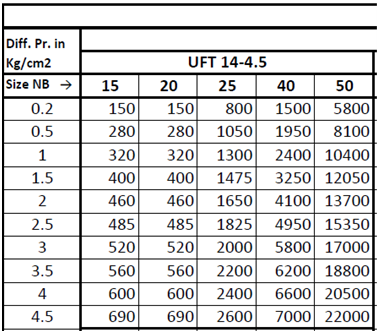

UKL trap carrying capacity chart for selection of Ball float trap:

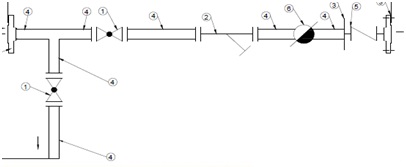

Trap with Flanged end connection:

Trap with Screwed ends/ Socket weld ends:

Operating Animation

Aerated Concrete Block Industry

Aerated Concrete Block Industry  Brewery Industry

Brewery Industry  Captive Cogen Industry

Captive Cogen Industry  Chemical Industry

Chemical Industry  Dairy Industry

Dairy Industry  Edible Oil Industry

Edible Oil Industry  Fertilizer Industry

Fertilizer Industry  Hotel Industry

Hotel Industry  Pharma Industry

Pharma Industry  Rice Industry

Rice Industry  Rubber Industry

Rubber Industry  Soap Industry

Soap Industry  Sugar Industry

Sugar Industry  Textile Industry

Textile Industry  Tyre Industry

Tyre Industry