Steam Trap is Leaking Live Steam

Steam Trap is Leaking Live Steam ?

Even a relatively new steam Trap seemingly in a new condition can fail if applied incorrectly. This can be understood by seeing the difference between the live steam or simply looking the flash steam.

Differance between Flash Steam & Live Steam

There is very minor difference between Live Steam & Flash Steam coming out from traps & unfortunately without checking we cannot differentiate between the two. Main reason for live steam are-

- Negative Pressure difference

- Under sizing

- Pressure blockage

- Group Tapping

Pressure & Vapors’ in Live steam at high velocity & with less condensate droplets at outlet of traps. Flash Steam is released from hot condensate when its pressure is reduced & this happen because of pressure difference between inlet & outlet of any traps

Causes of Vapor Clouds at the Outlet of Steam Trap.

Condensate Come out from pipe & discharge to atmosphere, flash steam is generated. Flash evaporation (or partial evaporation) is the partial vapor that occurs when a saturated liquid stream undergoes a reduction in pressure by passing through a throttling valve or other throttling device. This process is one of the simplest unit operations.

In flash Steam only small portion of mass convert into flash due to pressure difference.

Steam Vapor

Due to change in specific volume from higher pressure to lower pressure flash steam vapor generated. This Flash steam quantity can be changed on higher side from high pressure to low pressure.

We can understand this by this example also-

Calculating the % Flash Steam Generated

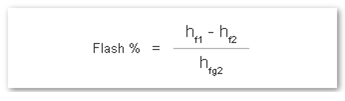

The % of flash steam generated (flash steam ratio) can be calculated from:

where:

- hf1= Specific Enthalpy of Saturated Water at Inlet*

- hf2= Specific Enthalpy of Saturated Water at Outlet

- hfg2= Latent Heat of Saturated Steam at Outlet

* In traps designed to have a significant amount of sub-cooling of the condensate before discharge, the sensible heat of condensate at the trap inlet can be significantly lower than when estimated using inlet pressure saturated steam values.

Please Note,

If the steam trap is of a thermostatic type or Bimetallic type the discharged condensate is sub-cooled below saturation temperature. The heat in the cooler condensate will be slightly less, and the amount of flash steam produced would be less.

If the trap discharged condensate at 15°C below the steam saturation temperature, then the available heat in the condensate would be less & We can calculate according to that.

Sub-cooling traps may exhibit less flash steam than traps with little or no sub-cooling; only non-sub-cooling traps are typically recommended for drip or high temperature tracer service to maintain safety and reliable operation.

Aerated Concrete Block Industry

Aerated Concrete Block Industry  Brewery Industry

Brewery Industry  Captive Cogen Industry

Captive Cogen Industry  Chemical Industry

Chemical Industry  Dairy Industry

Dairy Industry  Edible Oil Industry

Edible Oil Industry  Fertilizer Industry

Fertilizer Industry  Hotel Industry

Hotel Industry  Pharma Industry

Pharma Industry  Rice Industry

Rice Industry  Rubber Industry

Rubber Industry  Soap Industry

Soap Industry  Sugar Industry

Sugar Industry  Textile Industry

Textile Industry  Tyre Industry

Tyre Industry