SELECTING STEAM TRAPS FOR LAUNDRIES AND PRESSES

There are innumerable 5-star hotels in India, so counting it would take a day! However, the most well-known brands belonging to this category include the Taj, Hilton, Leela Palace, Grand Hyatt, etc to name a few.

Steam Utilization areas in Hotels are:-

1) Laundries:-

- Washing Machines.

- Dry cleaning machine.

- Dryers.

- Calendar.

- Press Machines.

- Other equipment's.

2) Kitchen:-

- Cookers.

- Dishwasher

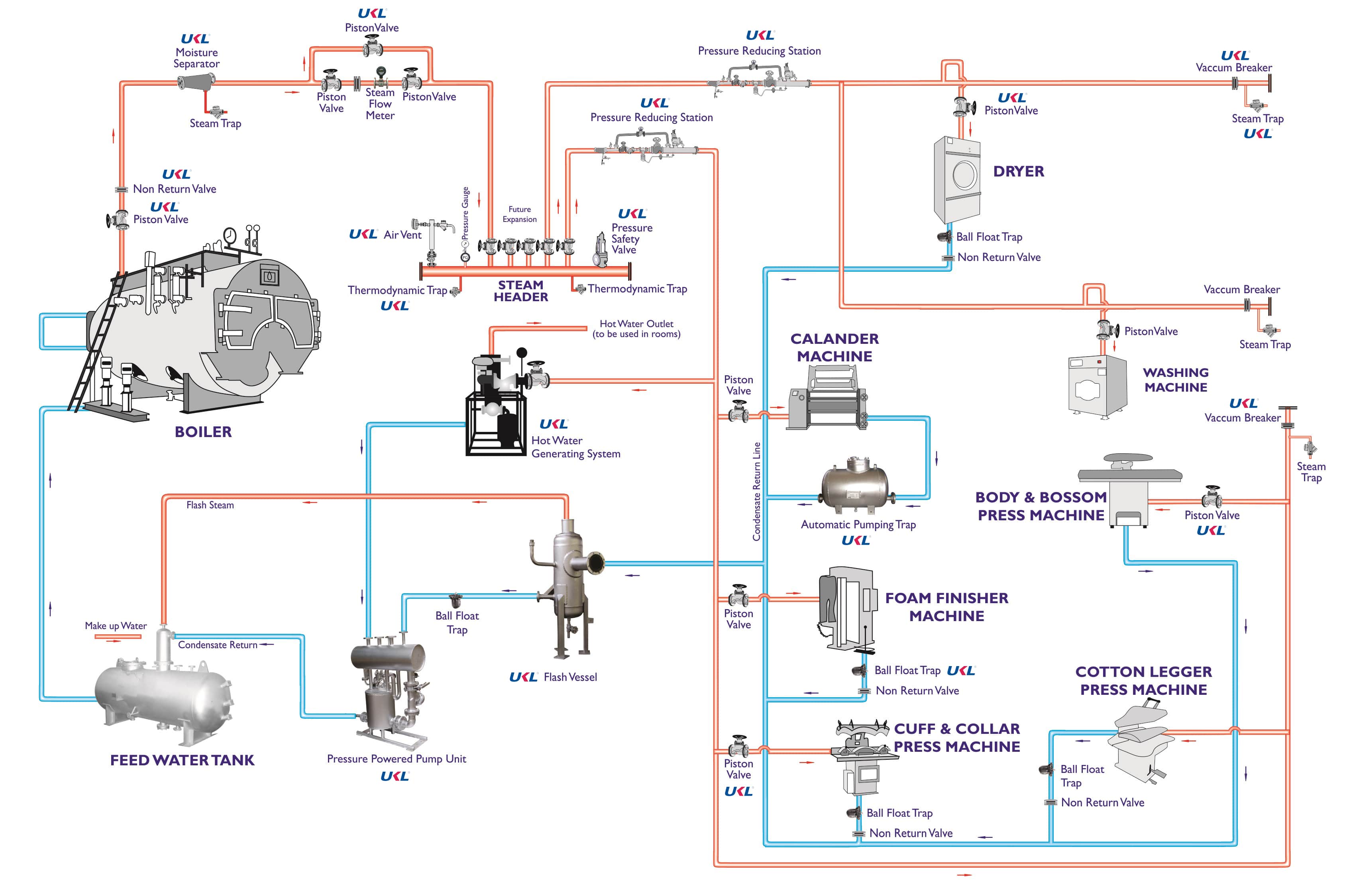

Diagram of UKL Products used in Hotel Industries.

Laundries:

The ‘laundry’ can be defined as a place where the washing and finishing of clothes and other washable articles are carried out.

Garment presses

In Hotel industry after generating steam in boiler it is distributed in major steam consuming equipment like Calendar, Dryer, Washing machine, Body & Bosom press machine, Foam machine, Cuff & Collar, Cotton logger machine.

Thermodynamic steam trap will be good choice for this application.

Ironers and calendars

It is mainly very Modern Equipment’s, & fully enclosed machines often have the traps fitted all at one end for ease of maintenance, with long pipes connecting the traps from the middle of the bottom of the beds to the drain points. Thermodynamic trap will effectively remove the condensate.

Dry cleaning machines

A dry-cleaning machine is similar to a combination of a domestic washing machine and clothes dryer. Garments are placed in the washing or extraction chamber (referred to as the 'basket' or 'drum'), which constitutes the core of the machine. The washing chamber contains a horizontal, perforated drum that rotates within an outer shell. The shell holds the solvent while the rotating drum holds the garment load. The basket capacity is between about 10 and 40 kg (22 to 88 lb). A Float trap with thermostatic vent can be good choice for removing condensate.

Tumble dryers

At times they use driers where product is stacked in trays, lined up in a cabinet. Steam is passed through a coil at the back of the cabinet to generate hot air used for drying. A blower will be usedto circulate the air. Float trap will effectively remove the condensate.

Tyre presses

Temperature to be maintain preciously avoid 'soft' cures. Accumulation of condensate will affect the quality of product, so it must be removed as it forms. Nitrogen (or other inert gases) are sometimes used to add internal pressure to the 'bladder' during the curing process. The trap must beable to remove the gas freely else the process times will be extended. Compact trap station with Inverted bucket steam trap will be best choice. Second choice will be float trap with thermostatic air vent.

Aerated Concrete Block Industry

Aerated Concrete Block Industry  Brewery Industry

Brewery Industry  Captive Cogen Industry

Captive Cogen Industry  Chemical Industry

Chemical Industry  Dairy Industry

Dairy Industry  Edible Oil Industry

Edible Oil Industry  Fertilizer Industry

Fertilizer Industry  Hotel Industry

Hotel Industry  Pharma Industry

Pharma Industry  Rice Industry

Rice Industry  Rubber Industry

Rubber Industry  Soap Industry

Soap Industry  Sugar Industry

Sugar Industry  Textile Industry

Textile Industry  Tyre Industry

Tyre Industry